but hopefully you can get some knowledge out of this.

first i bought a board that is called: 1/8" smooth panel board

then i cust it down to a reasonably size that i still knew was too big... measure twice cut once

so i got it cut to shape, very hard to do by yourself so try to get some help allthough i did it by myself. it wasnt fun though

and then after i got the shape (with about an extra in. on each side to allow for the reduction of size when its molded) i got my old iron that i use for waxing snowboards since it is adjustable hotness, has no holes on the bottom and was $1.00 at the thrift store.

and i got the squirt bottle we use to squirt the doggy

so...

here is the board cut to shape

here is why it is best to mold the corners

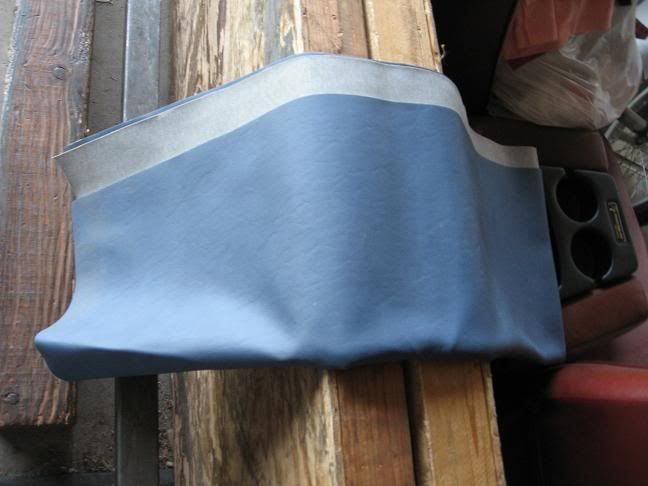

blue vinyl:

hanging from roof loosely

my weapon of choice, cuts through the board very nicely

iron and spray bottle for molding

i sprayed the board at the corner and got it soaked, then put weight on it to get it to bend. wait 10 min. and it should have a denent bend to it

flipped it over and this is what you get:

did the other side:

like i said, i never got to applying the vinyl (with spray adhensive that i bought) onto the board and installing it so i cant show a finished result.

let me know what you think of my legit craftsmanship

the board is pretty darn stiff so it can support some speakers